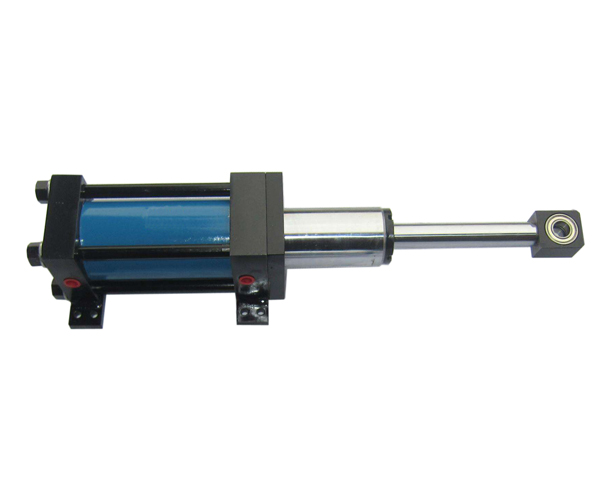

3.5Mpa hydraulic cylinder标准拉杆液压缸

塞姆克油缸、系统分厂主要从事各种液压油缸,液压系统的设计,制造及技术咨询与服务等项目,并致力于各种非标液压油缸及高性能油缸的研发。

目前公司聘请了多名有三十几年工作经验的知名专家为本公司的工程师及技术顾问。我们生产的液压油缸有四拉杆型,DG型车辆用液压缸,HSG系列液压缸,Y系列冶金用液压缸,大通径重型液压缸,以及各种非标液压缸。

Seric’s cylinder and system branch plant is mainly engaged in a variety of hydraulic cylinders, hydraulic system design, manufacturing and technical consultation and service projects, and committed to a variety of non-standard hydraulic cylinders and high-performance cylinder research and development. At present, the company has hired a number of well-known experts with more than 30 years of working experience for the company's engineers and technical consultants. Now we produce a variety of standard hydraulic cylinder, vehicle hydraulic cylinder, metallurgical hydraulic cylinder, large diameter heavy hydraulic cylinder, as well as a variety of non-standard hydraulic cylinders.

3.5Mpa CTJ型标准液压缸,为了对应以机床为首的一般工业机械广泛用途,备有多种支承型式。塞姆克油缸、系统分厂主要从事各种液压油缸,液压系统的设计,制造及技术咨询与服务等项目,并致力于各种非标液压油缸及高性能油缸的研发。

目前公司聘请了多名有三十几年工作经验的知名专家为本公司的工程师及技术顾问。我们生产的液压油缸有四拉杆型,DG型车辆用液压缸,HSG系列液压缸,Y系列冶金用液压缸,大通径重型液压缸,以及各种非标液压缸。

Seric’s cylinder and system branch plant is mainly engaged in a variety of hydraulic cylinders, hydraulic system design, manufacturing and technical consultation and service projects, and committed to a variety of non-standard hydraulic cylinders and high-performance cylinder research and development. At present, the company has hired a number of well-known experts with more than 30 years of working experience for the company's engineers and technical consultants. Now we produce a variety of standard hydraulic cylinder, vehicle hydraulic cylinder, metallurgical hydraulic cylinder, large diameter heavy hydraulic cylinder, as well as a variety of non-standard hydraulic cylinders.

另有液压缸本体上装有滑动式接近开关,容易检测位置的带有接近开关的CJT型标准液压缸已系列化。(详情请与我们联系)

参数specification

| 项目 | CJT35-※※※※※-※※※-20 | ||

| 缸内径 mm |

32、40、50、63、80 100、125、160 |

||

| 支承型式 | SD、LA、LB、FA、FB、CA、CB、TA、TC | ||

| 工作压力 | 3.5Mpa | ||

| 最高允许压力 | 4.5MPa | ||

| 耐压 | 5.0Mpa | ||

| 最低工作压力 | 0.1MPa | ||

| 最高工作速度 | 300mm/s | ||

| 最低工作速度 | 8mm/s | ||

|

★1 最大行程 mm |

缸内径 | 32 | 800 |

| 40 | 1000 | ||

| 50、63 | 1200 | ||

| 80 | 1600 | ||

| 100 | 1600 | ||

| 125、160 | 1800 | ||

| 行程允差 | 参照列表★2 | ||

| 活塞杆头部螺纹精度 | JIS B 0211-6g(2级) | ||

| 环境温度范围 | -10~+80℃ | ||

● 大致质量由下式计算

【质量】=【基本质量】+【行程100mm增加质量x行程/100】。

★1、因受纵向弯曲强度上的限制,最大行程上有变化。

★2.行程的允差

|

行程 mm |

允差 mm |

| 小于100 | +0.8 0 |

| 超过100小于250 | +1.0 0 |

| 超过250小于630 | +1.25 0 |

| 超过630小于1000 | +1.4 0 |

| 超过1000小于1600 | +1.6 0 |

| 超过1600小于2000 | +1.8 0 |

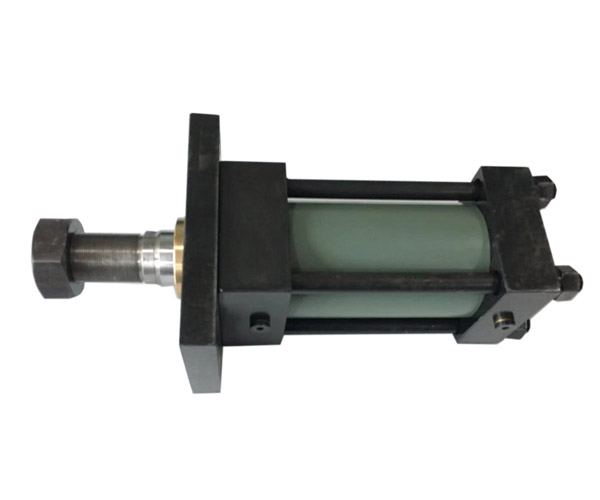

■支承型式

| 标记 | 名称 | 标记 | 名称 |

| SD | 基本型 | CA | 单耳环形 |

| LA | 横向底脚型 | CB | 杆头盖销型 |

| LB | 纵向底脚型 | TA | 杆头盖销轴型 |

| FA | 杆侧长方法兰型 | TC | 中间销轴型 |

| FB | 缸头侧长方法兰型 |

86-20-82674399

86-20-82674399

在线咨询

在线咨询